Pump suction lifter pressure gauge with angle for lifting frame by Karl Dahm

The pump suction lifter with manometer with angle for the lifting frame, in case

.

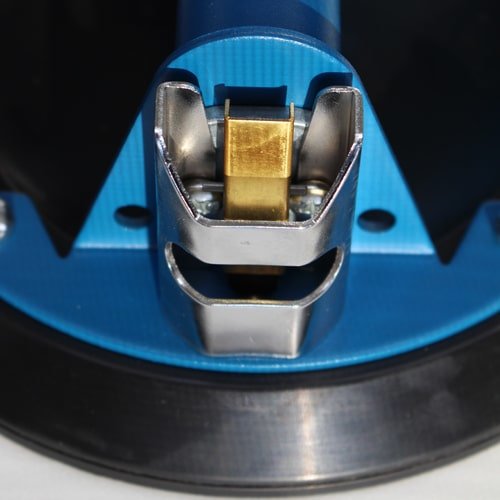

The pump suction lifter with manometer uses vacuum for lifting and lifting loads up to 120 kg, such as tiles in large formats. In addition, the pump-operated vacuum lifter with pressure gauge allows for a quick, convenient and easy condition. For fixing, the pump button is pumped until it is sucked in. The pressure gauge is used to monitor the pressure and hold of the pump suction lifter with pressure gauge.

As soon as a loss of pressure is indicated on the pressure gauge, it must be pumped up again. The practical case offers additional protection and comfort when transporting or storing the pump lifter. By means of a manual pump, the air between the rubber pad and the contact surface is removed - this is called vacuum. A red line on the pump piston indicates the vacuum. The non-return valve allows the user to pump up the suction pad again after a loss of vacuum. This increases the suction pressure again.

This can be done without removing the pump lifter from the contact surface. By means of a release mechanism button on the other side of the handle, one can completely release the pump suction lifter with pressure gauge. With the pump-operated suction lifter, the transport of tiles is simplified, whereby the removal is just as uncomplicated as the application / suction. The pump suction lifter has a capacity and load-bearing capacity of up to 120 kg. When attaching it, you should ensure that the surface to which you want to attach it is clean and as dust-free as possible. Consequently, you should not leave any residues of oil or grease on the material, as moisture or dirt can reduce the slip resistance.

The multi-lip pump suction lifter from Karl Dahm nevertheless makes it possible to easily transport even structured material such as. It is also possible to easily transport structured material such as wood-look tiles. We strongly advise against moistening the pump-operated suction lifter with a pressure gauge, as is the case with conventional pressure lifters. Pumping will otherwise bring the moisture into the inside of the siphon. This can only be completely dried out if the pump lifter is dismantled professionally.

How to use the pump suction lifter with pressure gauge Suction of the pump suction lifter with pressure gauge:

- Position the hand cup on the dust-free contact surface, the red line should be visible

- Now pump the wand until the rubber suction plate is fully attached. Once the red line is covered, there is enough vacuum to lift

- It is important that you regularly check the suction cup to make sure that it is still securely attached. If the red line appears, set the load down immediately and pump the plunger until you no longer see the red line

Loosening the pump suction lift with manometer :

- Place the load on a safe surface or directly in the tile adhesive.

- Pull one of the release tabs or push the release lever of the valve until the Karl Dahm pump suction lifter is completely unlocked.

Maintenance of the pump-operated siphon with pressure gauge:

If the pump-operated siphon does not work normally, the siphon surface may be dirty or the cup may need maintenance. Then first clean the surface according to the instructions. If the condition does not ächange, contact our customer service on 08667-8780. Cleaning the pumping siphon with pressure gauge is that easy.

- Remove the air filter from the suction plate surface

- Clean the surface of the tray with a little soapy water or glass cleaner. To prevent liquid from getting into the pump, hold the cup face down or cover the suction hole in the filter recess

- Remove all debris from the suction plate surface

- Let the rubber suction plate dry and replace the air filter

Inspection Inspect the pump-suction lifter regularly and make sure that it does not have any of the following defects:

- Cuts or damage to the sealing edges of the rubber pad.

- Cracks or dents on the handle or the pump

- Appearance of the red line shortly after the suction plate is attached

- Sluggishness or dramatic change in pump movement

- Excessive glaze or stiffness of the rubber pad

- Air filter missing from the suction plate surface

You should correct all faults before using the suction plate.

Karl Dahm has been promising the best quality for 65 years. Therefore, our goal is also to provide you with the best products.

This goal is reflected in the positive returns on our products and services. We would like to thank you for your loyalty.

The pump suction lifter with manometer with angle for the lifting frame, in case

.

The pump suction lifter with manometer uses vacuum for lifting and lifting loads up to 120 kg, such as tiles in large formats. In addition, the pump-operated vacuum lifter with pressure gauge allows for a quick, convenient and easy condition. For fixing, the pump button is pumped until it is sucked in. The pressure gauge is used to monitor the pressure and hold of the pump suction lifter with pressure gauge.

As soon as a loss of pressure is indicated on the pressure gauge, it must be pumped up again. The practical case offers additional protection and comfort when transporting or storing the pump lifter. By means of a manual pump, the air between the rubber pad and the contact surface is removed - this is called vacuum. A red line on the pump piston indicates the vacuum. The non-return valve allows the user to pump up the suction pad again after a loss of vacuum. This increases the suction pressure again.

This can be done without removing the pump lifter from the contact surface. By means of a release mechanism button on the other side of the handle, one can completely release the pump suction lifter with pressure gauge. With the pump-operated suction lifter, the transport of tiles is simplified, whereby the removal is just as uncomplicated as the application / suction. The pump suction lifter has a capacity and load-bearing capacity of up to 120 kg. When attaching it, you should ensure that the surface to which you want to attach it is clean and as dust-free as possible. Consequently, you should not leave any residues of oil or grease on the material, as moisture or dirt can reduce the slip resistance.

The multi-lip pump suction lifter from Karl Dahm nevertheless makes it possible to easily transport even structured material such as. It is also possible to easily transport structured material such as wood-look tiles. We strongly advise against moistening the pump-operated suction lifter with a pressure gauge, as is the case with conventional pressure lifters. Pumping will otherwise bring the moisture into the inside of the siphon. This can only be completely dried out if the pump lifter is dismantled professionally.

How to use the pump suction lifter with pressure gauge Suction of the pump suction lifter with pressure gauge:

- Position the hand cup on the dust-free contact surface, the red line should be visible

- Now pump the wand until the rubber suction plate is fully attached. Once the red line is covered, there is enough vacuum to lift

- It is important that you regularly check the suction cup to make sure that it is still securely attached. If the red line appears, set the load down immediately and pump the plunger until you no longer see the red line

Loosening the pump suction lift with manometer :

- Place the load on a safe surface or directly in the tile adhesive.

- Pull one of the release tabs or push the release lever of the valve until the Karl Dahm pump suction lifter is completely unlocked.

Maintenance of the pump-operated siphon with pressure gauge:

If the pump-operated siphon does not work normally, the siphon surface may be dirty or the cup may need maintenance. Then first clean the surface according to the instructions. If the condition does not ächange, contact our customer service on 08667-8780. Cleaning the pumping siphon with pressure gauge is that easy.

- Remove the air filter from the suction plate surface

- Clean the surface of the tray with a little soapy water or glass cleaner. To prevent liquid from getting into the pump, hold the cup face down or cover the suction hole in the filter recess

- Remove all debris from the suction plate surface

- Let the rubber suction plate dry and replace the air filter

Inspection Inspect the pump-suction lifter regularly and make sure that it does not have any of the following defects:

- Cuts or damage to the sealing edges of the rubber pad.

- Cracks or dents on the handle or the pump

- Appearance of the red line shortly after the suction plate is attached

- Sluggishness or dramatic change in pump movement

- Excessive glaze or stiffness of the rubber pad

- Air filter missing from the suction plate surface

You should correct all faults before using the suction plate.

Karl Dahm has been promising the best quality for 65 years. Therefore, our goal is also to provide you with the best products.

This goal is reflected in the positive returns on our products and services. We would like to thank you for your loyalty.